Ecolite™ Steel Stiffener

Introduction

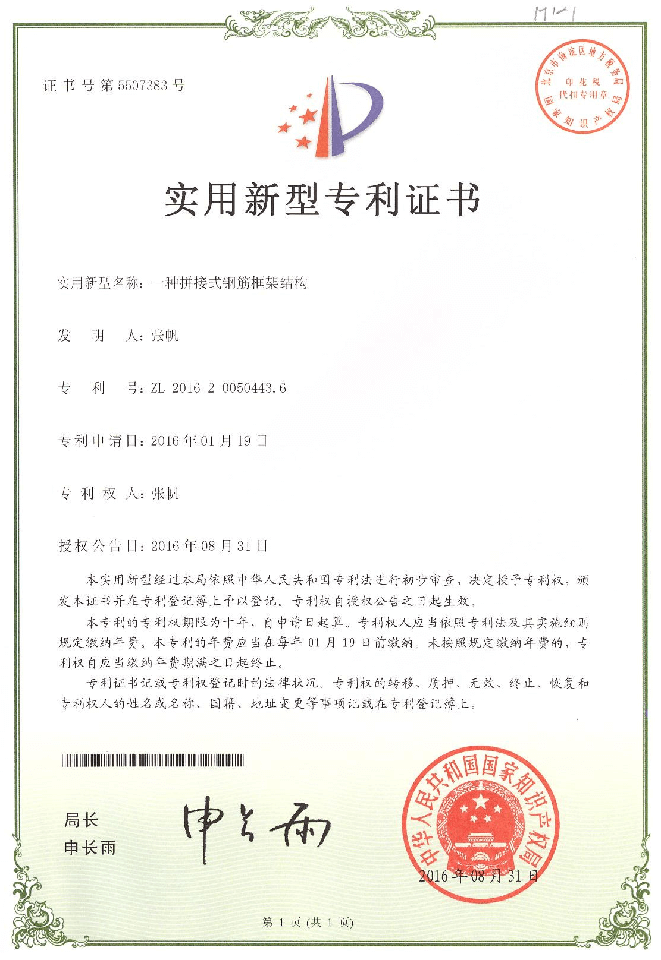

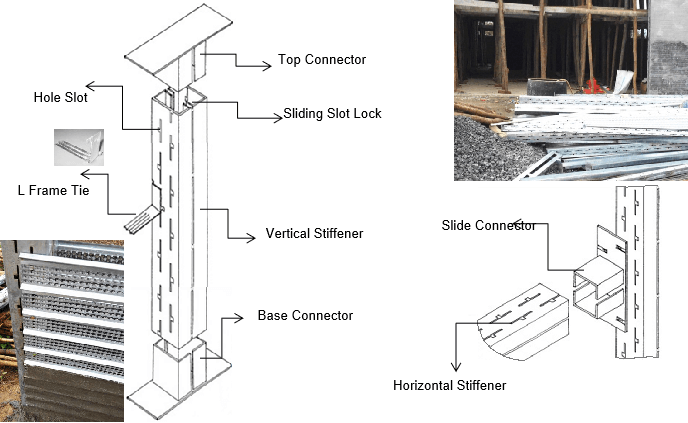

- Ecolite stiffener systems comprises of both horizontal and vertical steel structure with different connectors or adapters. The length and width of the stiffener can be customized for different building designs and application.

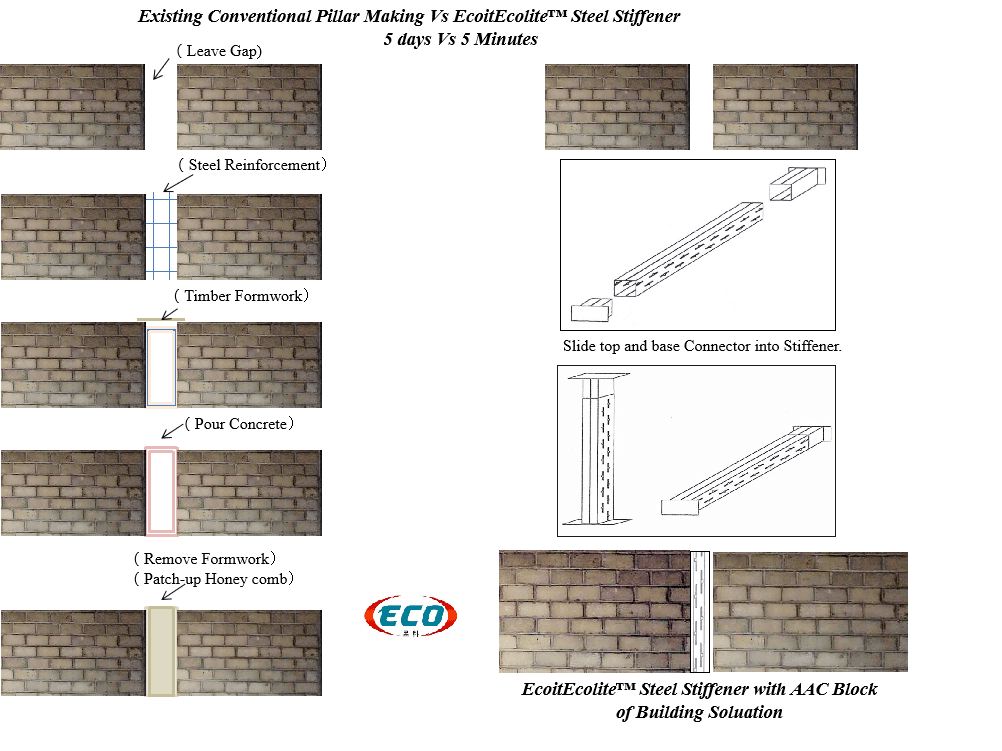

- The Ecolite modular stiffener are make of steel and can be set up in minutes by using bolts and nuts, slide and lock system, do not require the needs for welding, only 2 labour need to complete the process and without using any machine. Which can greatly improve the efficiency of construction, reduce labor costs and simple structure, easy to implement.

Product Description

- Ecolite™ Steel Stiffener (Powder Coated, Hot-Dipped Galvanised Steel, Stainless Steel and Mild Steel)

- Ecolite’s is a type of modular system of Steel stiffener, connectors and wall ties for both internal and external wall. (Pre-cast wall are suitable).

- In 1986, we manufacture GI Steel Lintels, Stiffeners for United Kingdom and United State of America Market.

- Ecolite’s Stiffener have CE approval.

- Patent Design and Application Usage (Patent No : 201620050443.6)

- Our products are supported by various country Trade and Development, Building and Construction Development Board.

Our GI Light Weight Stiffener can be lifted and installed easily without using any equipment. Construction can be begin immediately after installed our Ecolite’s Stiffener.

Our Steel Stiffener uses simple sliding system (similar to racking system), bolts and nuts are uses on based Junction when needed. Other than that, no welding are required.

We can provide Powder Coated steels, Hot-dipped galvanised steels, Mild steel and stainless Stiffeners.

Ecolite’s Stiffener can be flexibility if use for all masonry types and its can withstands up to earthquakes of magnitude 10

Fire resistance : Up to 4 hours rating.

Sound Proof : Sound transmission loss is better that normal Steel lintels.

Features

- Plastering on precast walls and floor slabs is not needed because of smooth finishing

- Production can continue in any weather condition.

- Better health and safety standards compared to conventional construction methods.

- The project can be better planned, managed and controlled. High speed can be achieved.

- Fast construction, less manpower required on site, and no shuttering required on site.

- Precast concrete is a durable material which requires less maintenance.

- Precast concrete has better fire resistance.

The benefits are as follows

- Less usage of reinforced concrete beams, cement, sandstone and construction materials

- Less waste of large amount of construction materials in various construction processes

- Less quantities of earth brick, AAC block, and wood, energy saving.

- On site installation, shortening the construction period

- Minimum lifespan of 100 years

- Structure in Modular system, assemble on site, less waste water, less environmental energy saving, less dust and noise pollution at site.

- From manufacturing, designing, assembling, constructing, Demolition and traditional Demolition concern compared to the traditional materials used (brick, concrete block and AAC block), construction efficiency saving by 90%.

Comparison between Existing Conventional Pillar Making Vs EcoitEcolite™ Steel Stiffener

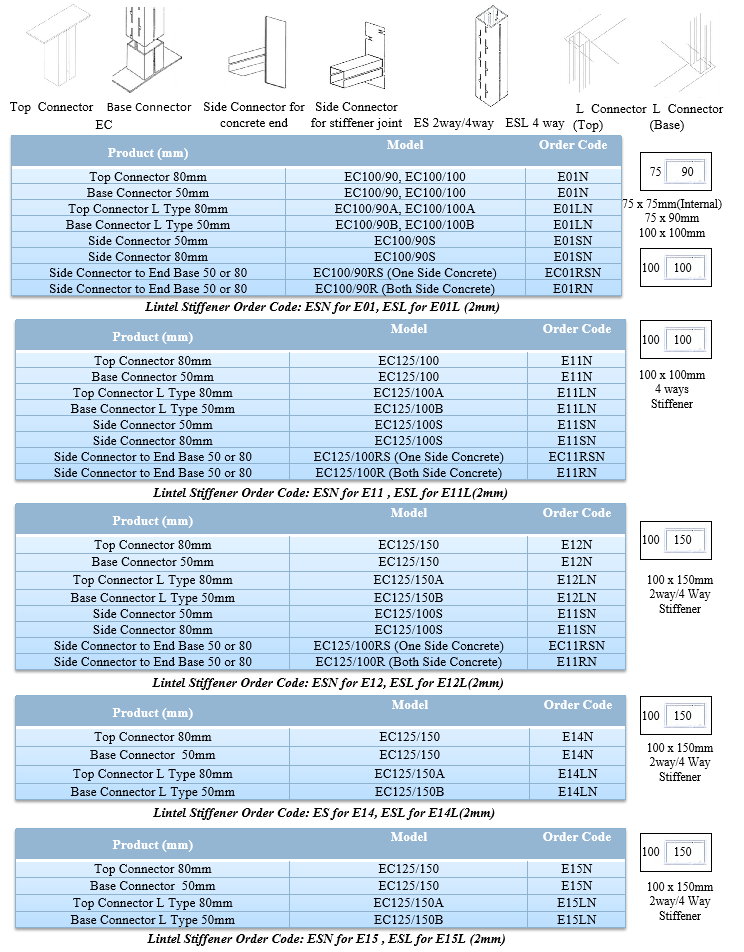

Steel Stiffener Series